Aluminum extrusion is a method through which aluminum composite material is passed through an area with a specific cross-sectional die.

The usage of aluminum extrusion in manufacturing and product design has increased largely in recent years.

Aluminum extrusion is just like squeezing toothpaste from a spout

An influential ram drives the aluminum through the die and it comes out from the die opening.

When it happens, it emerges in the exact shape as the die and is drawn out along a rotating belt.

At an essential level, the procedure of aluminum extrusion is comparatively easy to understand.

The force applied is the same as you force apply while squeezing a toothpaste tube with your hand.

As you squeeze tube, the toothpaste comes out in the shape of the tube’s die.

The opening of the toothpaste basically serves a similar function like extrusion die. As the opening is in the shape of a circle, the toothpaste will emerge as an extended solid extrusion.

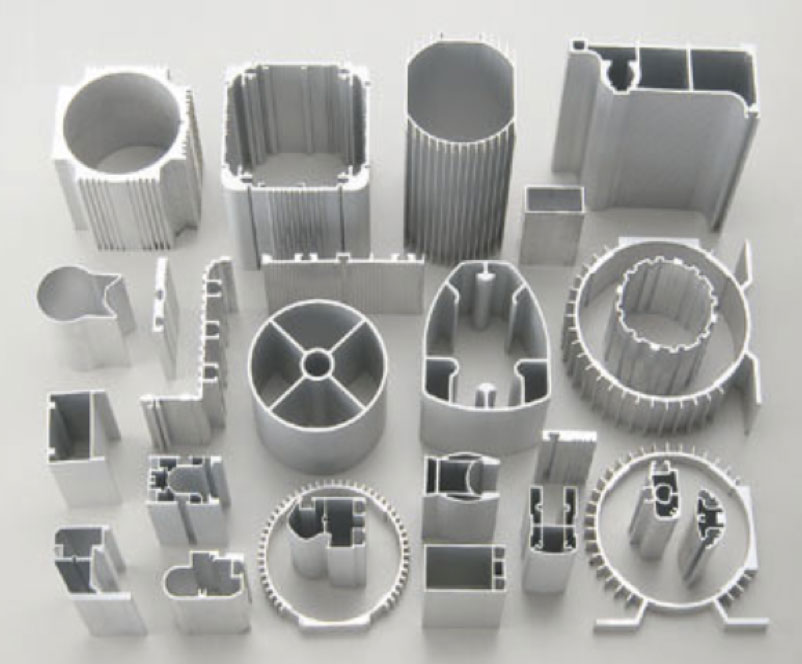

Below, are some examples of the most frequent extrusion shapes: angles, round tubes, and channels.

What Kind of Shapes can be extruded?

There are three main types of extruded shapes:

1. Solid, with no openings or empty spaces (i.e. an angle, rod, or beam).

2. Hollow, with at least one or more empty voids (i.e. rectangular or square tube).

3. Semi-hollow, with a partly enclosed space (i.e. a “C” channel with a small gap)

Extrusion has countless applications across numerous different manufacturing industries, including the energy, architectural, automotive, electronics, aerospace, and other trades.

The following are a few examples of more difficult shapes that were prepared for the architectural industry.

As you can see from above that the 1st and 2nd images are not made from just one but from multiple extrusions.

The designer’s shaped structures of multiple, interconnecting shapes. The black piece in the center is actually a polyamide thermal break and is used for insulation, and the grey pieces are aluminum.

Five Common Applications

Making a classified list would mean discuss definitions and whether to use dollars, tons or yards. The following are the most common aluminum extrusion application.

Architecture

This kind of application varies from balustrades and railings to build benches and frontages. As the extruded aluminum part is lightweight and stiff it’s perfect for applications such as shelters where the structure can’t weigh greatly but need to handle the weight. (Great stiffness means you require less of it, which provides extra weight-saving.) It appears smart and as it also doesn’t rust, placed in the rain isn’t a problem.

Automotive

Aluminum extrusion is also best for automotive uses such as trailers. Having a low weight of trailer lets your vehicle give more of its force to carrying the material you actually want to transfer and fewer to pulling the trailer itself. It’s also used widely in RVs for a similar reason; also it won’t rust and can be colored to look more attractive like chrome, so it’s worthy for decoration too.

Display equipment

Nearly every stand you have usually placed at an exhibition or a trade show was designed with a great portion of extruded material. It is because extruded portion can be made so sections interlock, manufacture assembly easy and quick. It’s easy to transport too, and it can be possible in a number of ways for a durable and attractive appearance.

In the same manner, display cabinets and point-of-sale displays are also examples of aluminum extrusion used to display products.

Framing

By using enclosures to connect lengths of extrusion fragments it’s easy to design different kinds of frames. Picture frames may be the most common, but a fast-growing use frames to carry solar panels. As these are usually placed on roofs, corrosion-resistant, aluminum’s lightweight nature creates it the perfect material.

Industrial

You can visit any industry, and you will see aluminum extrusion is placed there. It’s the best material for equipment like carts, workbenches, and inspection tables because it’s easy to drill and cut, lightweight however firm, and good value-for-money. It also has the additional attraction of being flexible: Like if a bench needs modification that can be done quickly and easily.

In the same industries, you’ll also see extrusion for machines. It goes together rapidly and can be fixed with Lexan boards for a clear vision however protecting workers working nearby.

China First Part Limited is expert in rapid prototyping, rapid tooling, low volume manufacturing, and finish service. Feel free to contact us on sales@firstpart.com for more information.